Unlock Your Imagination: The Ultimate Guide to T-Shirt Screen Printing Success

In the globe of t-shirt screen printing, the journey from principle to creation is both rewarding and complex. Understanding the essential methods and devices is vital for anyone wanting to generate top quality layouts that reverberate with their target market. This overview aims to light up the essential actions and finest techniques that can elevate your screen printing endeavors. The course to success is not merely about grasping the craft; it likewise entails critical marketing to efficiently display your one-of-a-kind offerings. What are the key insights that can change your strategy to this creative process?

Recognizing Screen Printing Essential

Comprehending the principles of screen printing is essential for any individual seeking to produce top notch personalized T-shirts. This flexible printing technique entails moving ink via a mesh screen onto material, permitting for sturdy and vibrant styles. The procedure begins with creating a stencil, referred to as a display, which is developed to block out locations where ink ought to not be used.

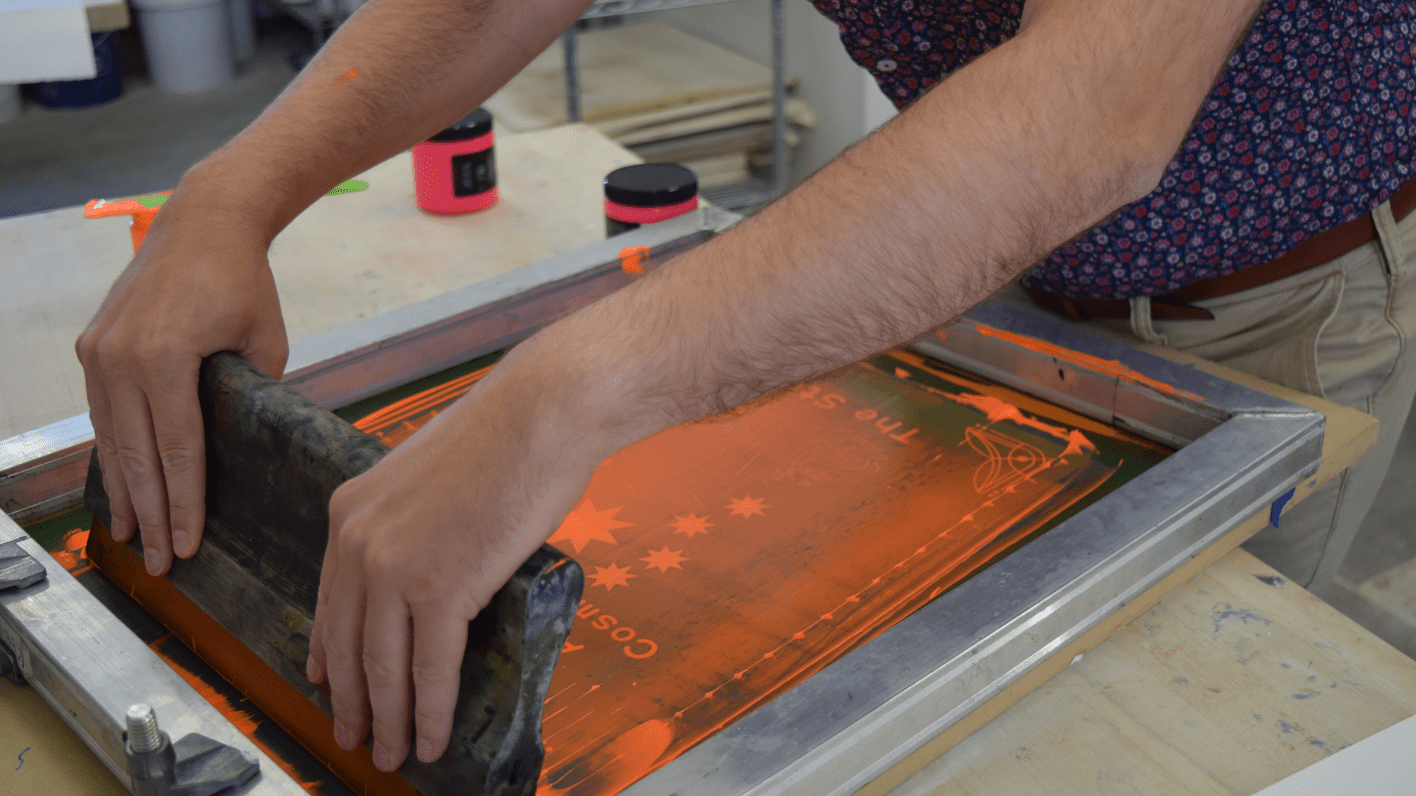

Once the screen is prepared, the textile is positioned under it, and ink is pressed via the mesh utilizing a squeegee - Abilene T-Shirt Screen Printing Company. This method enables specific application and can accommodate different shades and styles. The appeal of screen printing hinges on its capacity to create big quantities of constant prints, making it a popular selection for events and companies

In addition, comprehending the complexities of screen printing can substantially impact the end product. Aspects such as ink thickness, mesh matter, and curing methods can affect the overall high quality and durability of the print. By mastering these fundamental concepts, people can ensure their custom-made T-shirts not just meet aesthetic expectations however additionally stand the test of time concerning wear and washability.

Vital Products and Equipments

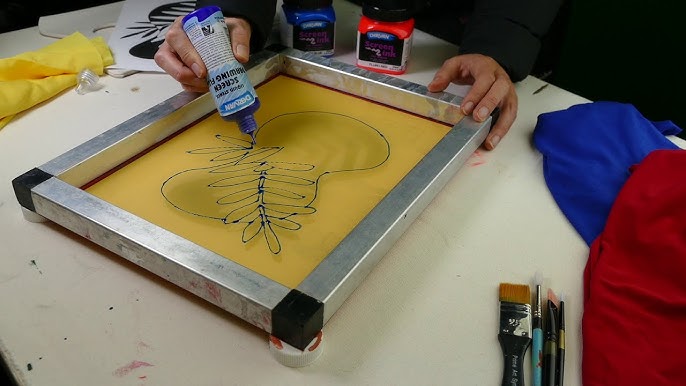

To effectively carry out screen printing, a choice of vital materials and tools is required. At the structure of any type of screen printing configuration is the screen itself, normally made of polyester mesh stretched over an aluminum or wooden framework (Screen Printing). This mesh holds the pattern that specifies the visuals to be printed

Next, you will certainly require a squeegee, a tool used to press ink via the screen onto the fabric. The kind of squeegee and its durometer (hardness) can influence the top quality of the print, so select one suitable for your task.

Additional products include emulsion and a light source for developing patterns, as well as tape for preventing and safeguarding the screen ink bleed. Lastly, an office outfitted with cleaning products will help with correct upkeep of your devices and screens, inevitably improving your printing effectiveness.

Designing Your T-Shirt Graphics

Creating engaging graphics for your T-shirts is an essential action in the screen printing procedure. The layout should not only catch interest yet additionally convey a message or motif efficiently. Begin by conceptualizing concepts that reverberate with your target audience. Think about existing fads, social references, or personal experiences that can influence one-of-a-kind styles.

Use style software application such as Adobe Illustrator or CorelDRAW to bring your concepts to life. Take note of color concept; choosing the best scheme can substantially affect the general charm of your graphics. Business Branding Services. Confirm that your style is high-resolution, ideally 300 DPI, to keep clearness when printed

Believe regarding the placement of your graphics on the Tee shirts. Typical areas consist of the front facility, back, or sleeves. Each placement has its own visual influence, so pick sensibly based on your style and target market. In addition, think about the type of ink and textile you will be utilizing, as these can influence the last appearance of your graphics.

Preparing Your Screens

Preparation is crucial for achieving premium screen prints - Screen Printing. The process begins with picking the appropriate mesh screen, as the mesh matter straight influences the information and quality of your prints. A finer mesh matter is suitable for complex layouts, while a coarser count works best for strong graphics

Next, make sure that your screens are tidy and cost-free from any type of impurities. Dust, grease, or leftover emulsion can endanger print high quality. Make use of a degreasing remedy to thoroughly cleanse the screens prior to applying the emulsion.

Using the solution uniformly is necessary, as any variances can bring about unwanted blemishes in the final print. Utilize an inside story coater for a smooth, uniform layer, and permit ample time for drying in a dark atmosphere to stay clear of direct exposure to light.

When dry, it's time to subject your displays utilizing a light resource. Adhere to the supplier's guidelines for exposure times to attain the ideal results. After direct exposure, rinse the screens carefully to expose your layout, ensuring that the locations implied to print are clear. Appropriately prepared displays will certainly establish the structure for an effective printing process, boosting the general top quality of your t-shirt styles.

The Printing Process Explained

Understanding the printing process is crucial for accomplishing top notch lead to screen printing - Abilene T-Shirt Screen Printing Company. This section will cover key components consisting of effective screen preparation methods, numerous ink application approaches, and the vital healing and ending up actions. Each of these components plays a significant duty in the total success of the printing project

Screen Preparation Methods

Efficient screen prep work is vital for accomplishing top notch prints in the screen printing procedure. The success of your prints largely depends upon the thorough preparation of the screen, which offers as the foundation for your design.

Start with choosing an appropriate screen mesh, as the mesh matter influences the information and opacity of your prints. A greater mesh matter is optimal for complex styles, while a lower count appropriates for bold graphics. Next, effectively degrease the screen to remove any kind of pollutants that could influence attachment. This action ensures that the emulsion sticks evenly to the screen surface.

After degreasing, use a light-sensitive solution making use of a scoop coater, making certain an uniform layer throughout the screen. Exposure to light will set the solution where it is not covered by your design, so it is vital to make use of a well-contrasted openness film for ideal results. Post-exposure, clean out the unexposed solution, disclosing the stencil for your style.

Ink Application Methods

Precision in ink application is crucial for accomplishing vivid and constant outcomes in the screen printing procedure. Different approaches can be employed to use ink properly, each with unique advantages depending upon the layout and material type.

One of the most usual technique is using a squeegee, which equally disperses ink across the screen to move the layout onto the substrate. The stress and angle at which the squeegee is held can considerably affect the ink's density and quality. For thorough or detailed styles, a better mesh screen can be utilized, enabling more precise ink application.

An additional approach is flooding finishing, where a layer of ink is very first spread throughout the screen before the actual printing stroke. This strategy ensures a consistent ink flow and minimizes the danger of smudging or uneven application.

For specific applications, specialty tools such as rollers or spray weapons may be utilized, offering extra convenience. Each technique requires ability and practice to master, however comprehending the nuances of ink application can incredibly improve the top quality of your screen printing job, resulting in durable and vibrant prints on your T-shirts.

Healing and Completing Actions

When the ink has been put on the Tee shirts, the following stage in the screen printing procedure entails healing and ending up the prints to validate toughness and quality. Treating is the crucial action that assures the ink adheres properly to the textile, stopping fading or peeling during using and cleaning. This is commonly attained through warmth, where the published tee shirts undergo a particular temperature level for an established duration, enabling the ink to bond with the fibers.

There are a number of techniques of healing, with the most common being the use of a conveyor dryer or a heat press. Conveyor clothes dryers offer constant warm and are appropriate for larger batches, while heat presses are excellent for smaller runs or specialty products. It is very important to keep track of the temperature and time precisely, as inadequate curing can lead to jeopardized prints.

Completing steps may include quality checks for print blemishes, cutting excess threads, or folding and packaging the shirts for delivery. Applying these treating and finishing procedures not just enhances the longevity of the prints but additionally adds to the general expert appearance of the end product, vital for consumer contentment.

Treating and Finishing Your Prints

Treating and completing your prints is an important action in the screen printing process, as it assures the longevity and vibrancy of the style. Understanding effective curing methods can considerably impact the end product, while resolving usual issues throughout this phase can boost total high quality. This area will explore the value of proper treating, different completing techniques, and exactly how to fix constant difficulties.

Value of Proper Healing

Making sure proper curing is important for accomplishing high-grade screen prints that are long lasting and aesthetically enticing. Curing refers to the procedure of using warm to the published ink, which creates chain reactions that strengthen the ink onto the fabric. This step is important for making sure that the ink sticks properly, protecting against problems such as splitting, fading, or peeling in time.

The healing process varies depending upon the sort of ink utilized; plastisol inks, for example, commonly call for a temperature level of around 320 ° F(160 ° C) for appropriate healing. Insufficient curing can bring about a series of problems, including poor wash resilience, which may result in the print weakening after just a few cleans.

Furthermore, appropriate curing enhances the vibrancy of the print colors, making certain that layouts keep their desired appearance. It is crucial to check the treating temperature and time accurately, using reputable devices such as a warmth press or conveyor clothes dryer.

Methods for Effective Finishing

Three vital strategies can substantially improve the ending up procedure of screen-printed T-shirts, guaranteeing both resilience and aesthetic charm. Effective curing is extremely important. Making use of a trustworthy heat resource, such as a conveyor dryer or warmth press, assurances that the ink reaches the appropriate temperature. This not just sets the ink yet likewise improves adhesion to the material, causing a lasting print.

Second, appropriate washing and drying approaches add significantly to the ending up top quality. After treating, permit the T-shirts to cool properly prior to managing. When cleaning, select cold water and moderate detergents to maintain the vibrancy of the shades. Air drying out is more effective, as it minimizes the risk of warm damage from clothes dryers.

Lastly, take into consideration post-curing treatments. Applying a heat press for a few secs after the first curing can additionally improve the ink's resilience and give a smoother surface. In addition, integrating finishing sprays or conditioners can improve the tactile feel of the fabric, elevating the overall quality of the T-shirt. By implementing these techniques, you can achieve a professional criterion in your screen-printed layouts, adding to client fulfillment and repeat organization.

Fixing Common Concerns

Despite proper techniques in position, issues can still develop during the treating and finishing stages of screen printing. One typical trouble is insufficient treating, which can result in prints that rinse or discolor quickly. To resolve this, validate your treating temperature level matches the manufacturer's requirements for the ink being made use of, usually around 320 ° F (160 ° C) Use a trustworthy warm resource, like a conveyor clothes dryer, and validate the temperature level with a warm gun.

An additional problem is under-exposure during the printing process, which can result in poor attachment and breaking. To fix this, examine your direct exposure times and readjust based on the particular solution and source of light.

Additionally, irregular surfaces can occur because of inappropriate application of the ending up spray or other too much ink application. To fix this, use a consistent layer of spray and verify that your squeegee method is uniform.

Constantly allow adequate time for prints to cool down before dealing with - Texas Screen Printing Experts. This lowers the threat of smudging and verifies the integrity of the layout. By following these guidelines, you can properly repair and improve the top quality of your screen-printed layouts

Tips for Advertising And Marketing Your T-Shirts

Efficiently marketing your t-shirts needs a blend of creative thinking and calculated preparation. Begin by determining your target audience; comprehending their preferences will assist your layout and promotional initiatives. Utilize social media sites systems to display your creations. Engaging visuals and compelling storytelling can aid develop a brand name identity that reverberates with potential customers.

Take advantage of influencer collaborations to increase your reach. Teaming up with individuals who align with your brand values can offer reliability and attract new fans. Furthermore, take into consideration running targeted advertisements on platforms like Facebook and Instagram to reach a larger target market, ensuring to tailor your messaging based on market understandings.

Do not overlook the power of neighborhood events and pop-up shops. Taking part in community markets or fairs enables you to attach straight with consumers and develop brand commitment. Offer limited-edition layouts or exclusive bargains to create seriousness.

Regularly Asked Questions

Just how Do I Select the Right Fabric for Screen Printing?

Choosing the appropriate material for screen printing involves considering factors such as texture, weight, and absorbency. Cotton blends are suitable for vibrant prints, while artificial fabrics provide sturdiness. Select materials compatible with your ink kind for best outcomes.

Can I Print on Colored or Dark Shirts?

Yes, you can publish on colored or dark t-shirts. Nevertheless, it is critical to make use of specialty inks, such as plastisol or discharge inks, which provide appropriate opacity to ensure dynamic and enduring layouts on darker materials.

What Is the most effective Means to Store My Screens?

To ensure longevity and optimal performance, store your screens level in a trendy, completely dry environment, far from straight sunshine. Usage protective covers to prevent dirt accumulation and avoid piling to avoid damages to the solution.

Exactly how Commonly Should I Tidy My Screens?

Routine cleaning of displays is necessary to preserve print top quality and long life. It is suggested to tidy displays immediately after use, making sure the elimination of ink and solution, therefore preventing accumulation and protecting peak performance.

What Are Common Errors to Prevent in Screen Printing?

Common errors in screen printing consist of improper screen stress, insufficient ink mixing, neglecting to tidy displays extensively, wrong exposure times, and stopping working to execute test prints. Each of these can significantly impact the last item's top quality.

At the foundation of any type of screen printing setup is the screen itself, generally made of polyester mesh stretched over a light weight aluminum or wooden frame. Reliable screen prep work is vital for accomplishing top notch prints in the screen printing procedure. Precision in ink application is essential for attaining constant and vibrant outcomes in the screen printing procedure. Once the ink has been used to the Tees, the next stage in the screen printing process entails healing and ending up the prints to validate toughness and top quality. Common blunders in screen printing include inappropriate screen tension, poor ink mixing, overlooking to clean screens completely, incorrect exposure times, and falling short to execute examination prints.